Ink Stamp | TORMACH CNC | Nylon MDS

Inspired by the Olin Electric Motorsports suspension team, I created a suspension-shaped ink stamp to use in future fundraising events.

To create this, I used SolidWorks CAD/CAM and the Tormach CNC provided by Olin College to mill out a pattern on a solid block of Nylon MDS.

The goal of this project was to design a stamp that could utilize the precision and speed of the Tormach CNC, in addition to learning the ropes of SolidWorks CAM.

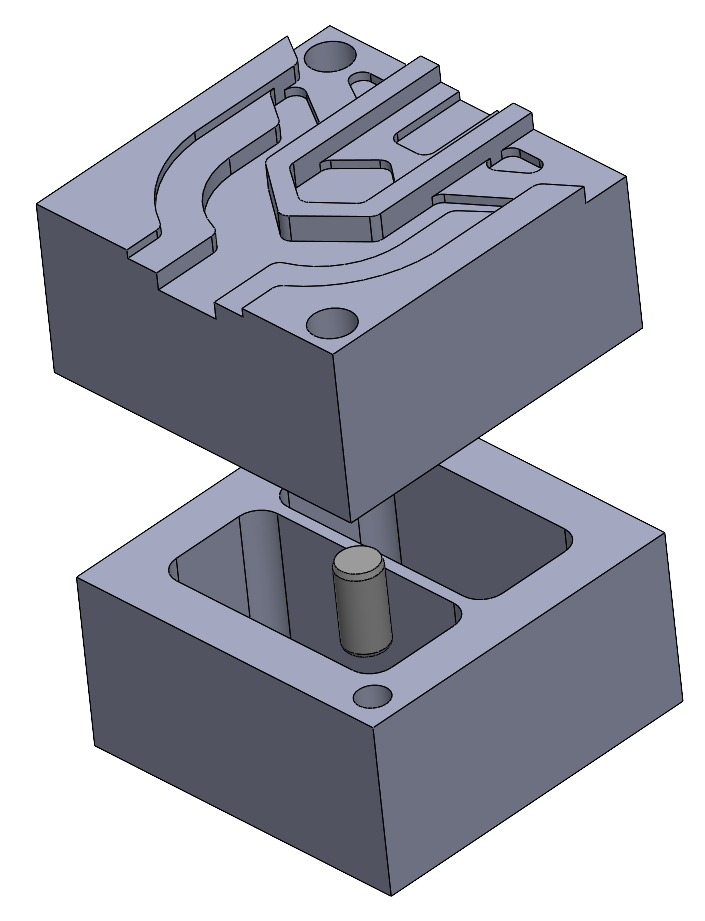

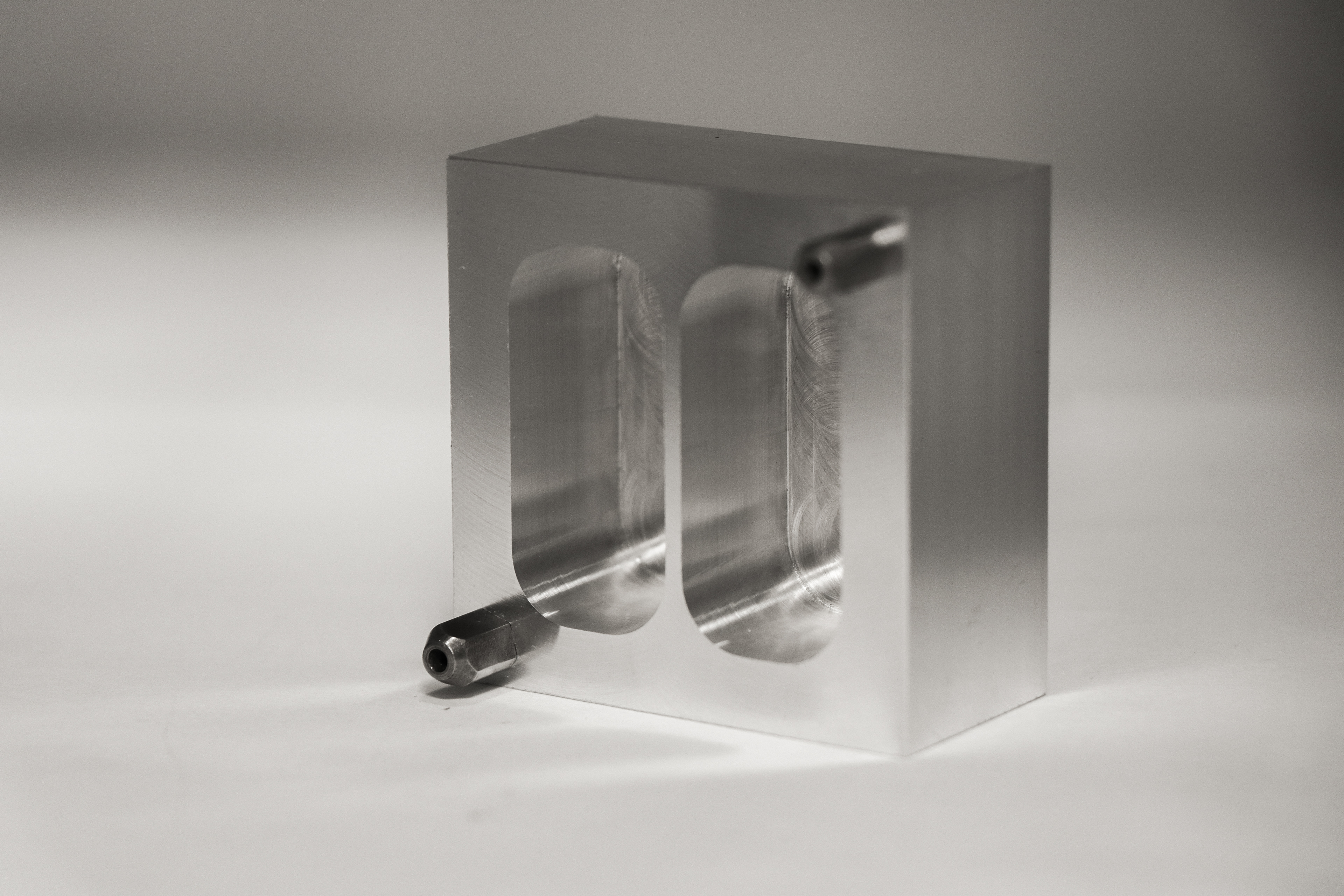

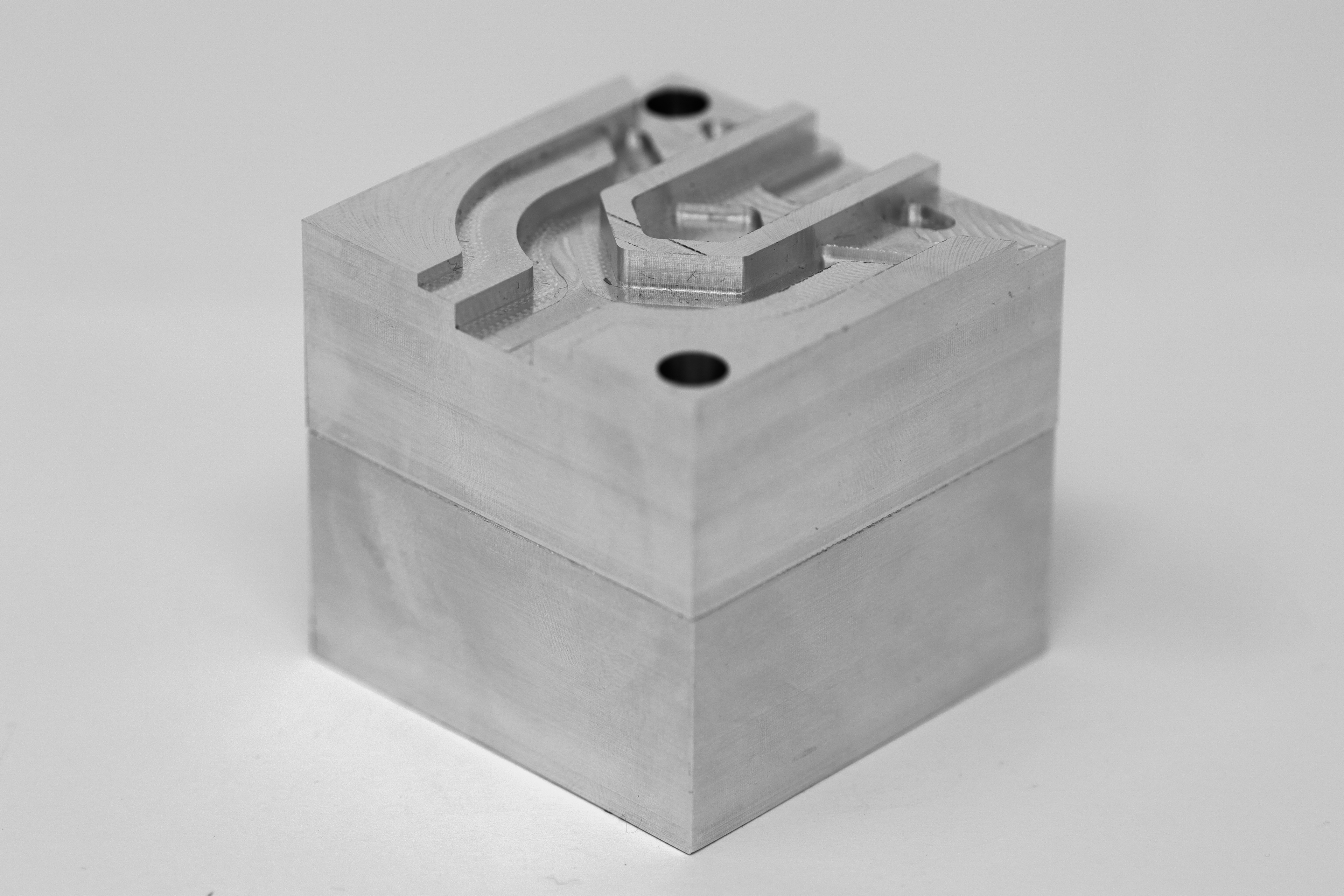

Treasure Box | TORMACH CNC | 6061 Aluminum

Using SolidWorks CAD/CAM and the Tormach CNC, I created a jewelry box with 6061 Aluminum as a base material.

The goal of this project was to manufacture a fashionable jewelry box that required minimal additional assembly labor in addition to a maximum of 30 minutes of machining time.

Inspiration of the box came from the popular video game, "League of Legends" Hextech Box.

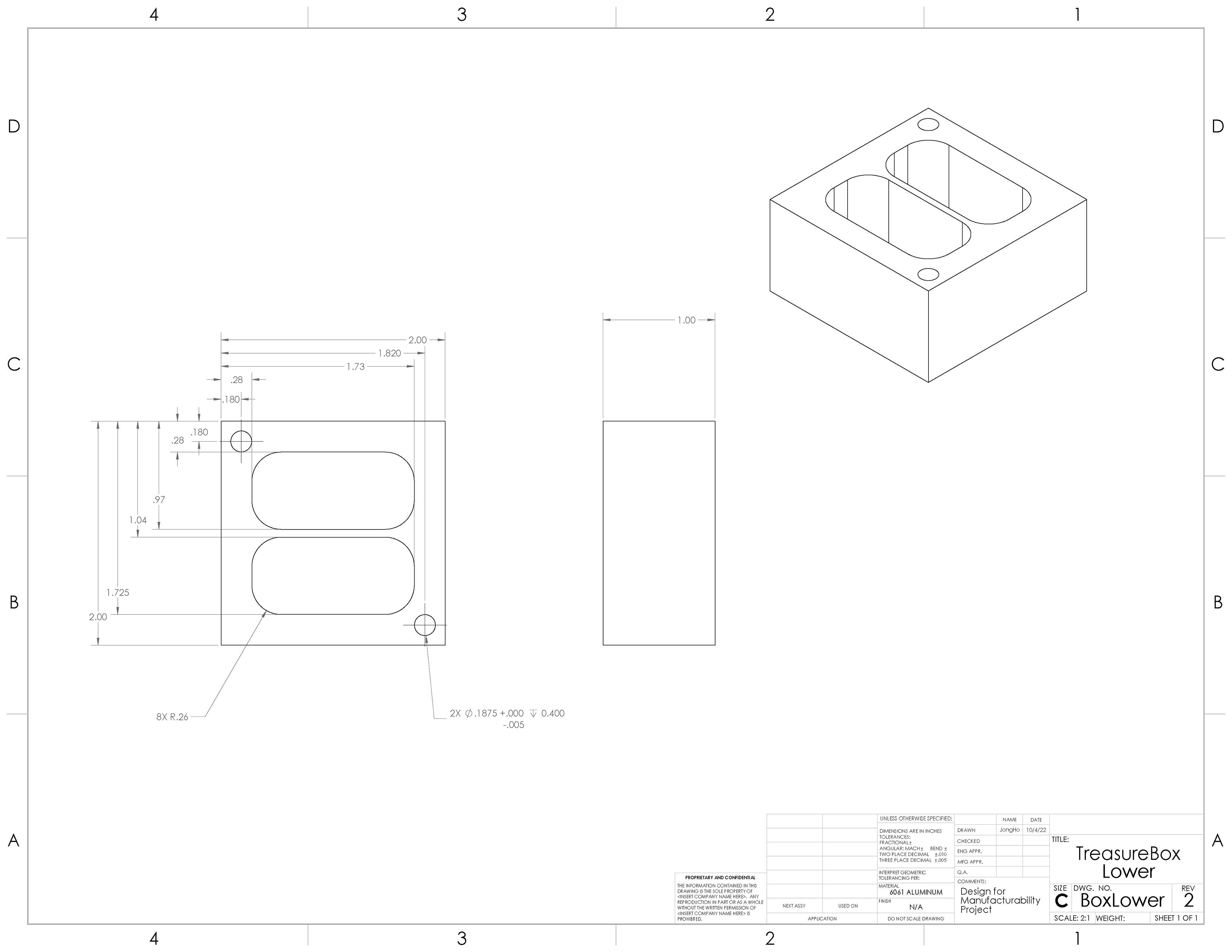

Two diamond pins slotted into force-fit holes were used as fasteners for when the box is in its closed state. Careful tolerancing and dimensioning were required to allow for seamless attachment of the diamond pins, and in conjunction, the two halves of the treasure box.

Technical drawing for the bottom half of the treasure box.

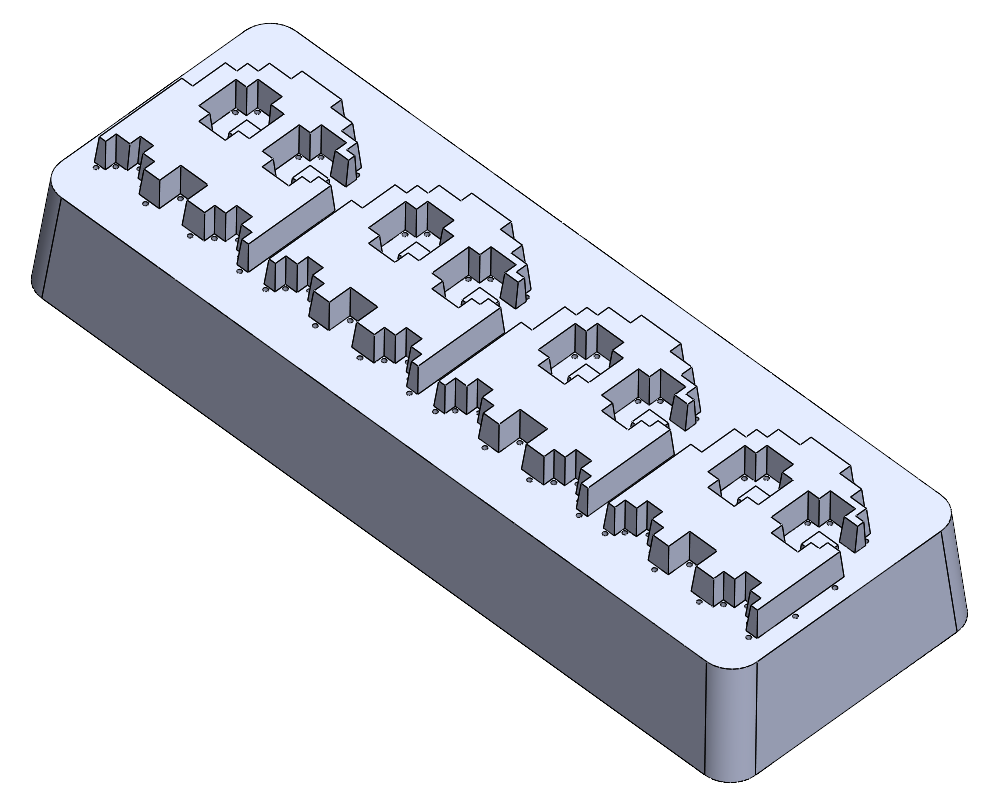

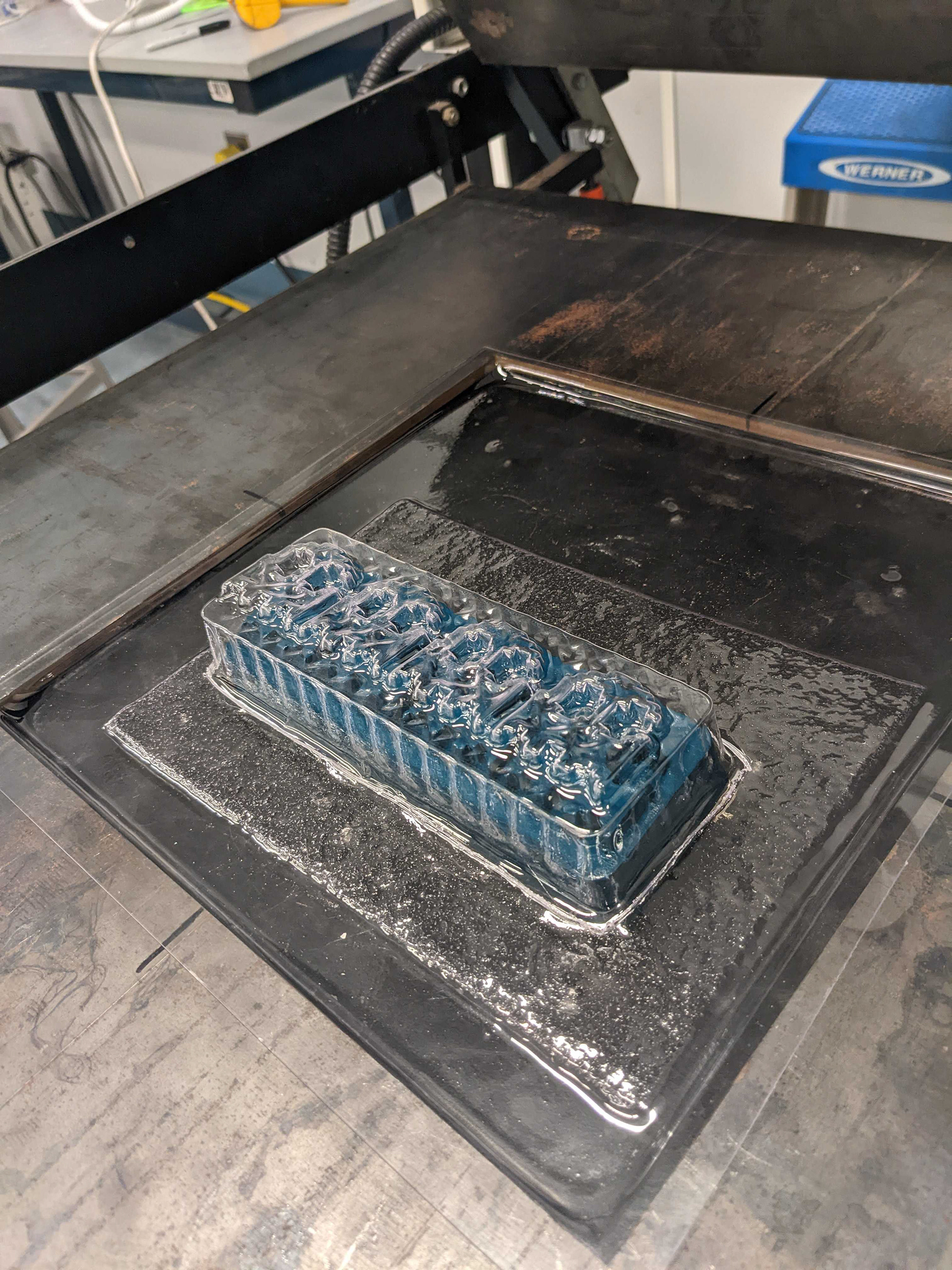

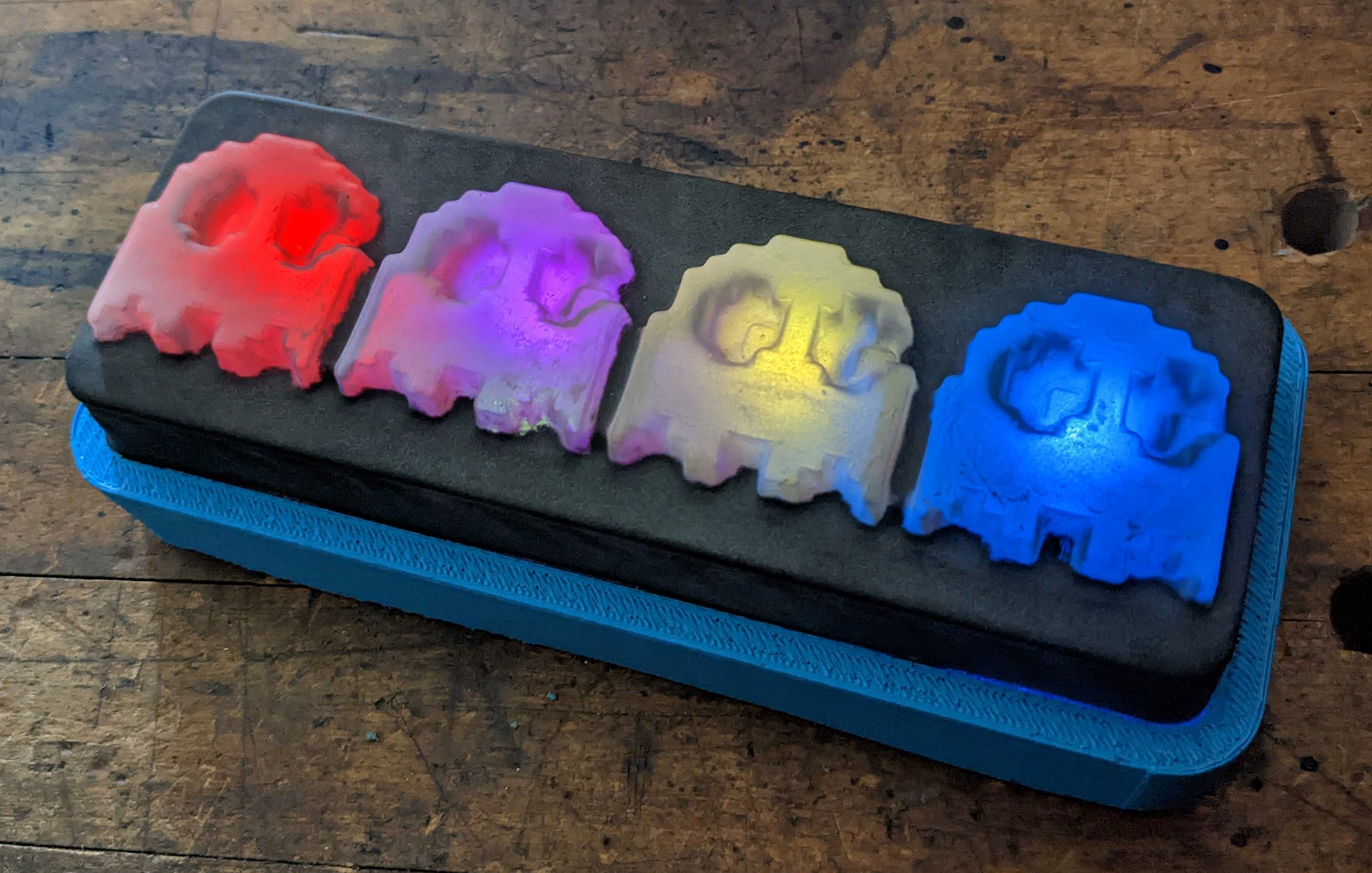

Ghost Night Light | Plastic Thermo-Forming & Casting | petg plastic & Urethane

Utilizing a combination of SolidWorks CAD, 3D FDM printing, and plastic thermo-forming processes, I created a battery operated nightlight that illuminates a ghostly aura of four pixelated ghosts.

In the spirit of Halloween, this nightlight was inspired by the adorable 8-bit ghosts that chase Pacman through the night. The goal of this project was to create a mass producible and cheap nightlight with minimal assembly processes.

The nightlight is created by plastic thermo-forming the ghost impressions on a sheet of PETG plastic over a 3D printed mold. Multiple bleed holes were placed near each edge to more firmly define the design of the ghosts. The PETG sheet is then sandblasted and spray painted to give a matte finish.

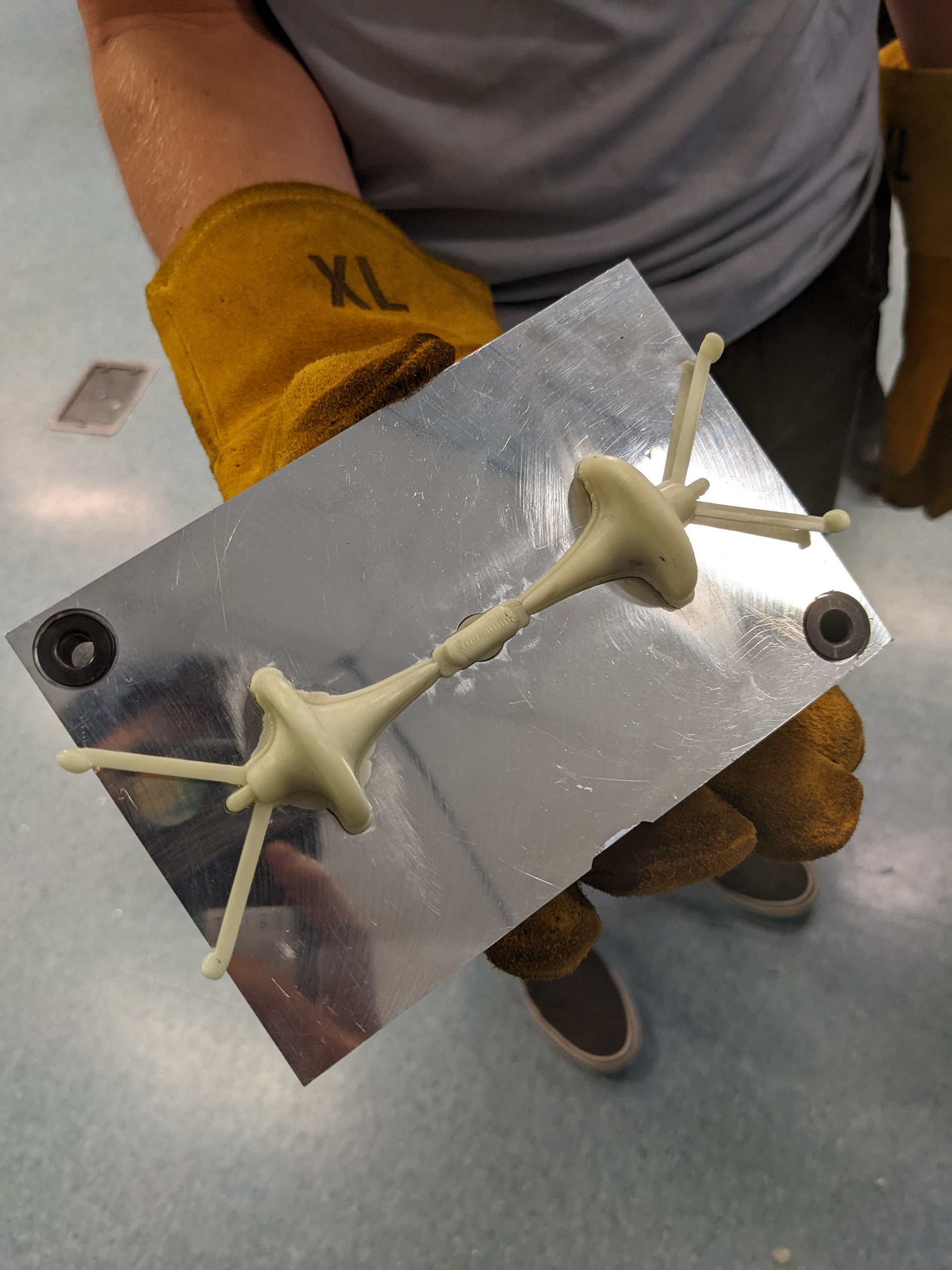

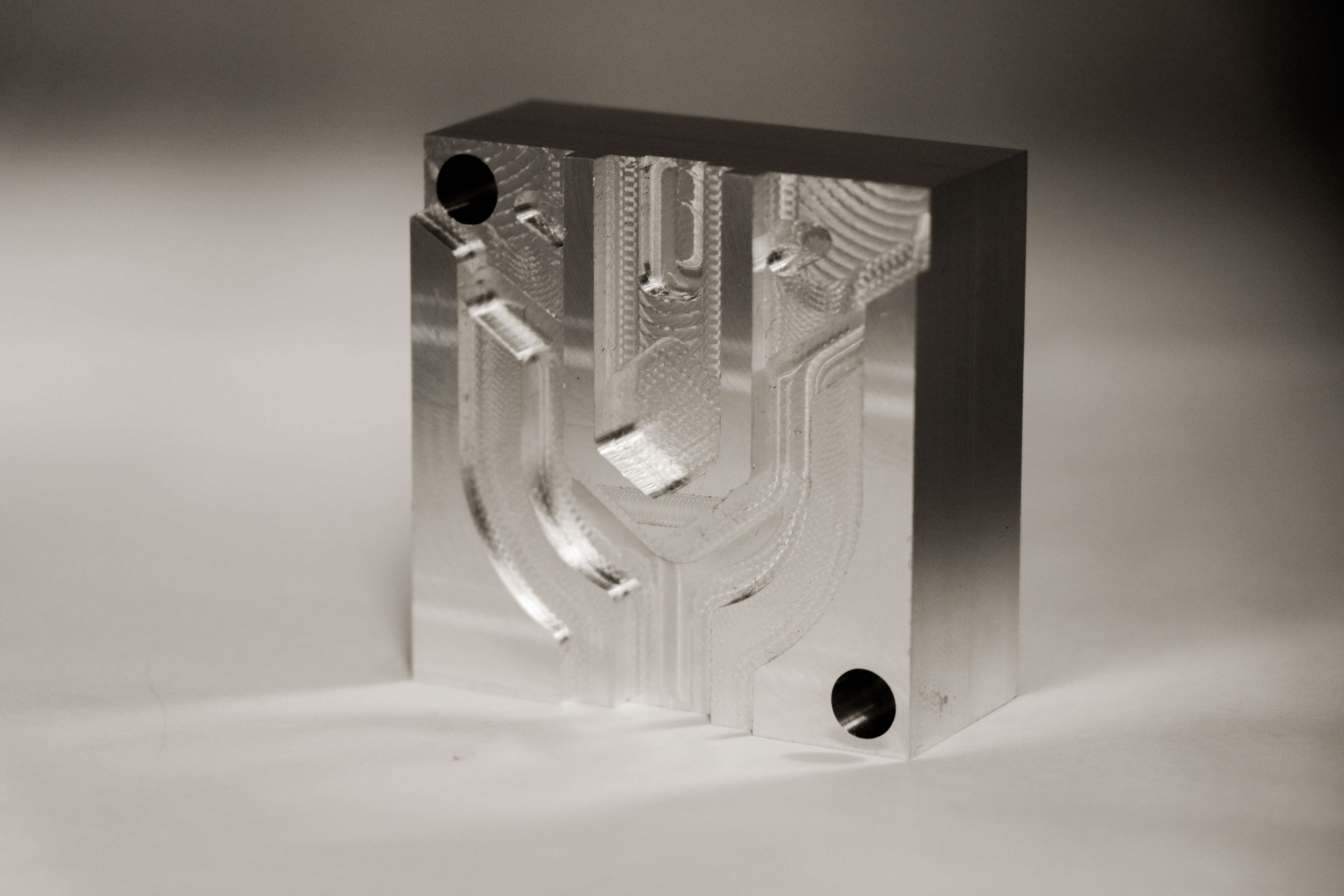

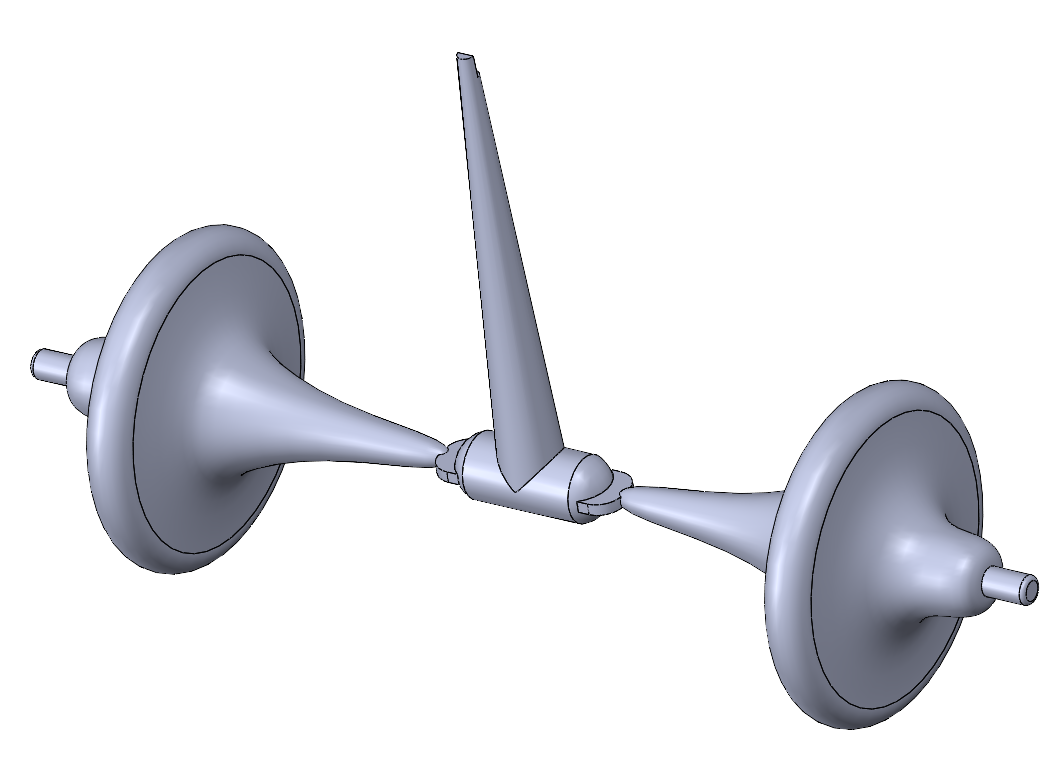

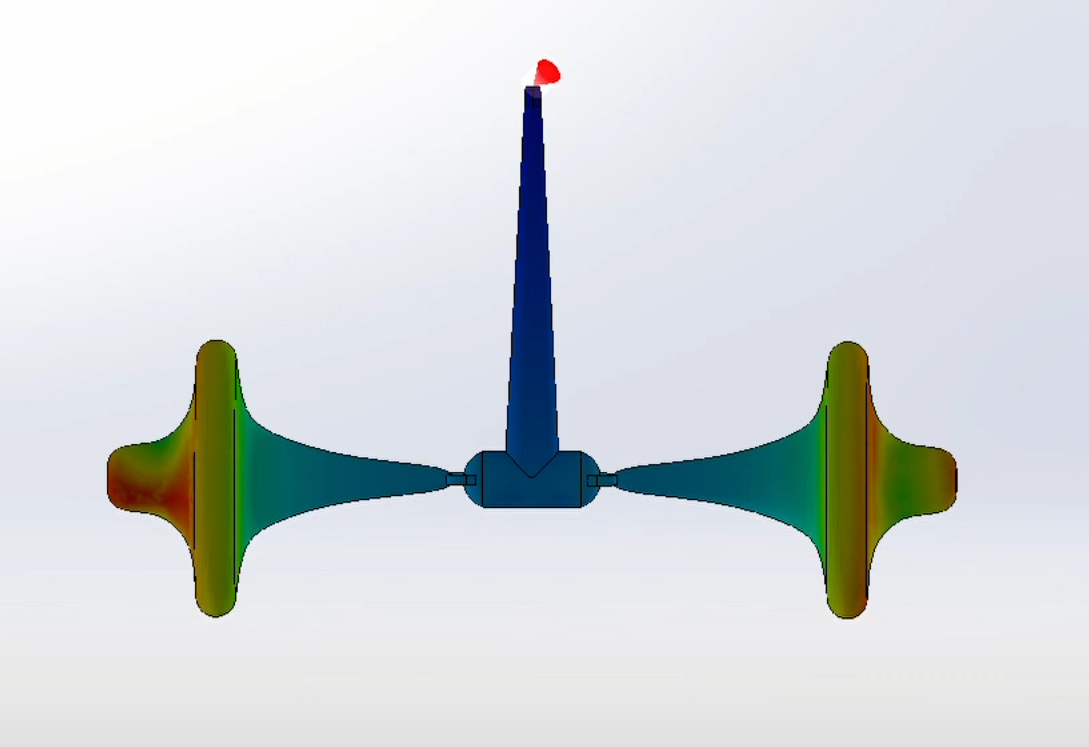

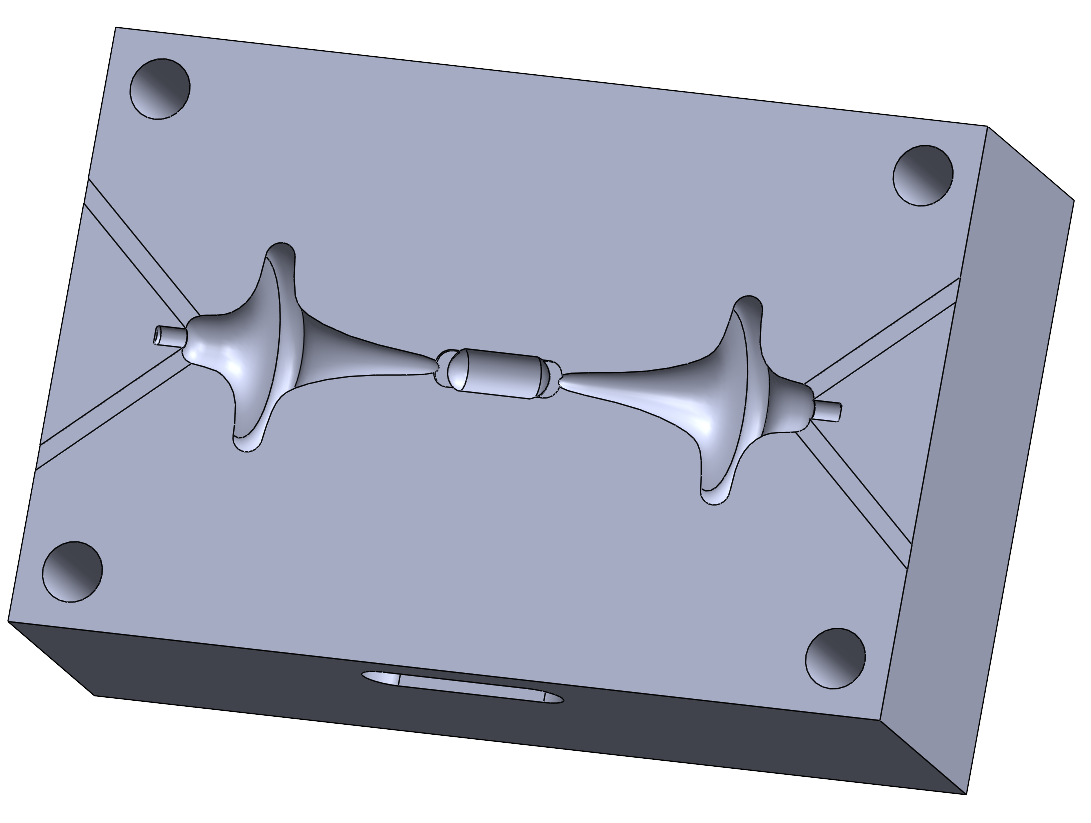

Spinning Scribe Top | INJECTION MOLDING | ABS Plastic

The goal of this project was to create a injection molded toy capable of being replicated in batches of 1,000-10,000 units. My classmate and I wanted to create a toy that was easily locatable in the dark that doubled as a scribe while in a shop setting.

To minimize injection failures, we performed CFD to determine potential air bubbles and/or flow irregularities before using the Tormach to mill out our mold.

A small tungsten rod was positioned inside the mold before injecting the plastic into the mold to minimize post-processing and ensure adequate adhesion.